repairing

Maine ships ranks it as, possibly, the oldest continuously operating private

shipyard in the nation.

repairing

Maine ships ranks it as, possibly, the oldest continuously operating private

shipyard in the nation.

Portland Towing Company's tug "Stanford" is the latest client

in a South Portland shipyard that was old when the Civil War was just a

cloud on the horizon. Since its founding by Portland entrepreneur,

Ezekiel Dyer, the venerable yard has done business in two locations

and has undergone a succession of name changes. Its unbroken

172 year history of building and  repairing

Maine ships ranks it as, possibly, the oldest continuously operating private

shipyard in the nation.

repairing

Maine ships ranks it as, possibly, the oldest continuously operating private

shipyard in the nation.

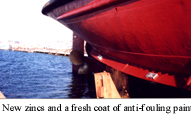

A week ago the "Stanford" rolled effortlessly up Maine Shipbuilding and Marine Railway Company's tracks and in a few days it will roll back with new zincs and a fresh coat of anitfouling paint. Prior to 1826 when Dyer, opened his first marine railway on Fore St. Portland, underwater hull repair was not quite as easy. To access the hull, a ship was beached and laboriously rolled up onto its side by hauling on lines attached to the mast tops. The process, known as careening, had to be repeated for each side of the hull. Dyer's new horse powered railway made careening woes thing of the past. It could crank a ship high and dry in minutes and relaunch it on the next high tide.

By mid-century Dyer's business was booming, but his days at the Fore St., Portland location were numbered. The city's original waterfront was rapidly disappearing under successive landfills. In 1853 the Grand Trunk Railroad filled in the yard's site for a new terminal and Dyer moved operations across the harbor to its present South Portland location. Under the new name, Cape Elizabeth Marine Railway it built sailing vessels, steamers and a fleet of Casco Bay Line ferries. In 1902, and several yard name changes later, Commodore Robert Peary's refitted survey ship, "Roosevelt" floated off the railway car on the sea borne leg of the Maine explorer's epic dash to the North Pole.

A high tech device in the yard's early days, the marine railway car

is basically a heavy duty boat trailer. Its flanged steel wheels

roll on tracks that slope up from the harbor and end amid a quadrangle

of weathered mid-19th century wooden buildings. One of them houses

the railway's 1890s hoisting engine. Each new ship that glides to

a touchdown on the submerged railway car arrives with its own unique

set of underwater hull contours. Yard Superintendent Arthur Randall's first problem is scoping out the new arrival's hull contours to insure

correct placement of the wood blocks that will support the vessel when

it is hauled high and dry.

first problem is scoping out the new arrival's hull contours to insure

correct placement of the wood blocks that will support the vessel when

it is hauled high and dry.

"If the vessel has a docking plan, it makes things easy," he says. "If the plans have been lost, I sometimes sweep the hull." The sweep, a bent rod attached to a handle, gives Randall an idea of a ship's underwater contours. "It takes a little time and its not too scientific. Sometimes you can locate a similar vessel and use its docking plans, but one way or another we get them out of the water."

Once familiar with a new ship's hull, Randall lines the railway car

with the three rows of stout wooden support blocks. The center

row supports the keel and takes most of the weight. The two outside rows

of "bilge blocks" press against the  more

fragile hull and keep the ship from toppling over. Their placement

is tricky; too low and the ship leans over, too high and they punch holes

through the hull.

more

fragile hull and keep the ship from toppling over. Their placement

is tricky; too low and the ship leans over, too high and they punch holes

through the hull.

On each docking, Randall is assisted by a diver who runs a safety check to make sure that the blocking conforms to the "hogs and sags" of aging ships. For a "hog backed" ship with a drooping bow and stern, the diver compensates with wedges placed under the keel amidships. Sagged ships get the wedges under the bow and stern.

"You don't have to hire a diver," said Randall, "its just cheap insurance. I program a ship a week and I don't have time to fix mistakes caused by docking."

When all is ready, Randall throws the power to a 1920s vintage 50 horsepower electric motor. The motor, replacing an original steam engine, cranks a massive set of 19th century reduction gears. A stout chain clanking over the smallest gear slowly inches the rail car out of the water.

"I use a lot of care setting them down," he said. "I've done them in 35 minutes, but generally it takes about an hour. Its only a 15 minute trip, but I go and stop, go and stop and ask questions."

Although Randall pays the diver extra to "swim the rail" and spot objects that have fallen onto the track, his ship-a-week schedule occasionally is knocked out by a derailment. One recent derailment put the yard out of business for a month.

"That time it was just because of a wire lobster trap that got dropped on the track." he said. "the game warden told us the owner was the only one who could move it. The trap's name tag was crushed by the rail car, so we never did find the owner."

Cleaning off marine growth, painting and propellor repairs fill most

of Maine Shipbuilding's schedule, but its nearly two-century old shipbuilding tradition continues. In 1995, a 72 foot

barge was built. The yard can handle repair jobs as large as engine

replacement or a small as installing fancy interior woodwork. Main

engine replacement often requires cutting an access hole through the hull.

two-century old shipbuilding tradition continues. In 1995, a 72 foot

barge was built. The yard can handle repair jobs as large as engine

replacement or a small as installing fancy interior woodwork. Main

engine replacement often requires cutting an access hole through the hull.

"If the engine is coming out through the side we weld on a temporary platform at the access hole and use the portable crane to slide the engine out of the boat," Randall explained. "We do redecking, paneling and galley installations, but basically what we like to do is bottom jobs. Get 'em in and out."

What is the future of a small shipyard poised at the beginning of its third century? According to Randall, 21st century environmental and safety regulation of its 145 year-old industrial site is one of the dark clouds on Maine shipbuilding's horizon. "There isn't enough money in this business to make everything modern again."

The yard's 10 employees complete about 180 jobs a year. Ten years ago, before government contract work dried up, 50 government vessels were repaired. Randall pointed out that bidding on the few government contracts that come along can be ruinously competitive.

"After a while you are just going through the exercise," he noted. "There are a lot of people out there hungry for contracts, but if you can't turn a new dollar for an old one, there's no sense wearing yourself out."

Another cloud over the venerable yards future, ironically, is its prime waterfront location. Randall described a New York developer's plan to cover the shipyard's lot with a hotel on pilings. Many of his neighbors eye the location for a park.

"Its too bad, because we'll get squeezed out," he says. "We will

eventually. Same as the farmers, we'll get squeezed out by the developers."